Since our founding in 1935, we have have worked tirelessly to refine the simple process of glass cutting.

As we meet the need to not only cut straight lines, but also cut curved lines and bore holes, while also seeking to improve the precision and speed of the cutting process, we have accumulated a wealth of knowledge and technology.

-

MDI

Cutting Edge Processing Solutions

- Overview -

Do you need to Scribe? Break? or Patterning ? for rigid substrates?

Please try MDI technologies.

Over 80years history and a lot of experiences in Glass processing

with laser and mechanical solution for FPD (Flat Panel Display),

Sheet Glass, Solar cells, and Electronics/Semiconductor .

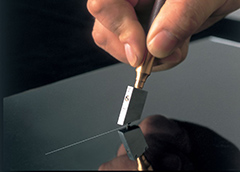

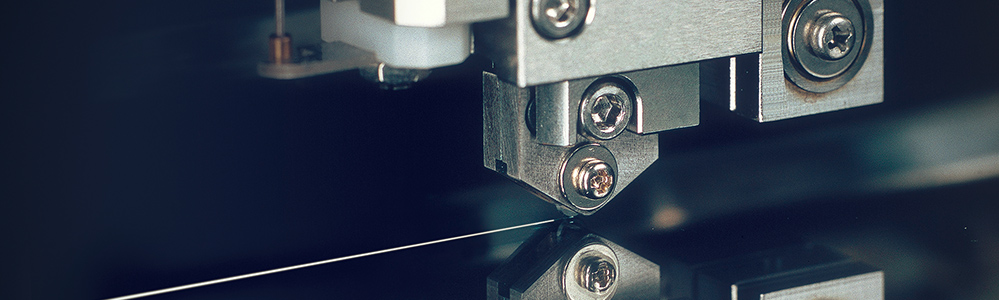

MDI scribing wheels are developed and manufactured at MDI

factory in Nagano,Japan ,Easy customizing and short lead time .

MDI is the only company in the world to provide the both scribing

tools , scribing wheels enhanced with appropriate process parameter.

MDI now put that knowledge to use, offering processing technology to cut and bore holes in glass, sapphire, fine ceramics, and all manner of other hard brittle materials.

Besides hard brittle materials, Mitsuboshi Diamond is also equipped to handle organic materials such as silicone resin, as well as materials made from copper and other metallic coatings layered in a pattern.

We are also proud to offer accurate patterning technology for precision scribing on film, developed for the processing of CIGS solar panels.

With these processing technologies at our disposal, we aim to be the only partner you ever need.

-

-

MUP Series

- Overview -

V-Motion Separator system.

1. Wheel scribing with high speed

2. Dry Process

2. NO thermal damage

3. NO kerf loss

Applicable for full automation system.

-

-

LS Series

- Overview -

High throughput dry process

1. Greatly improves productivity by cutting post-firing

substrates with a high speed dry process.

(Eliminates previously necessary post- processing,

such as groove cutting and polishing)

2. Even compatible with substrates that warp after

firing,using the warped scribe feature

3. Besides LTCC,also compatible with 300mm angle or

less glass substrates,and brittle material cutting

-

-

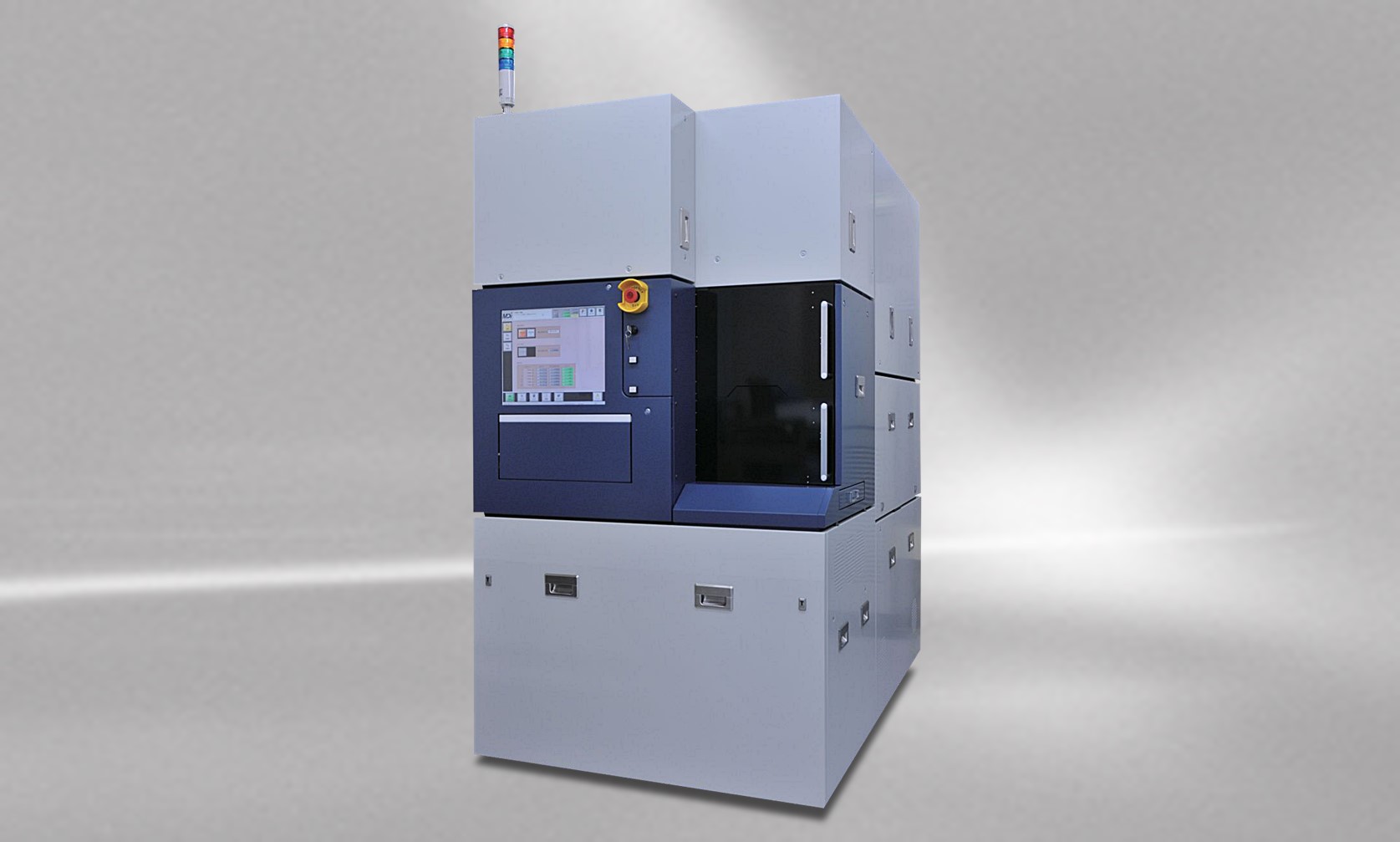

T6 Series

- Overview -

Makes smooth, super high precision X/Y scribes using our

unique optical system and automatic alignment features

The T6 series is brittle material processing laser

equipment designed mainly for the LED industry.

It achieves a higher grade and faster work-ability than Previous RAPYULAS series.

[Merits]

• New laser compatible with high luminance LEDs

• Much faster than older models

-

-

Accessories

- Overview -

We have a wide variety of Accessories for your products.

Solidbow is a tool primarily designed for cutting the resin on

the substrate surface of touch panels.

Because the Solidbow shares its shapes with the Mrcs ®,it can easily be fitted on MDI equipment with a Mrcs ® holder joint.

-

Following information is here ⇒ https://www.mitsuboshidiamond.com/en/![]()