-

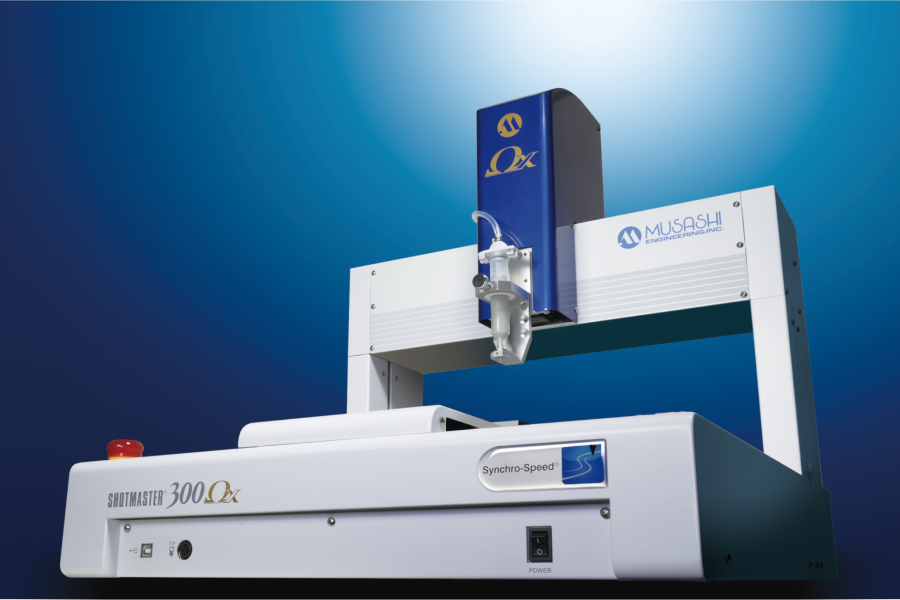

Desk Top Robot

ShotMaster SX/Ω series

- Overview -

Motion unit of concentration MUSASHI of dispensing

core technology.

1. High speed

800mm/s Highway movement (SX series) of class

top-level

2. High precise

We realize improvement of yield by high-level

dispensing quality.

3. High rigidity

Stable movement (ΩX series) high-speed as for

heavy tool and work

4. Full function, optional group

[New development] synchronized speed ®

function Equipped.

[new feature] kantansutedakino

[new model] Teaching Pendant

(program copy function Equipped between robot)

[optional] nozzle adjuster

[communication] high speed USB communication

Equipped

5. It can carry

[tall handloom tions] image recognition

function 350PCSmart (ΩX series)

Specifications for ΩX series

Series name SHOTmini200ΩX SHOTMASTER300ΩX SHOTMASTER400ΩX SHOTMASTER500ΩX Model SM200OMEGAX

-3A-SSSM300OMEGAX

-3A-SSSM400OMEGAX

-3A-SSSM500OMEGAX

-3A-SSControl number of shaft center 3 axes Movement

RangeThe X, Y-axis 200mm 300mm 400mm 500mm The Z-axis 80mm kahan

Weight

(*2)The Y-axis (the work base side) 20 kg Z,W axis (the head side) 15 kg Power supply, Power consumption AC100 - 240V 50/60Hz External form

DimensionsW 380mm 510mm 610mm 710mm D 460mm 570mm 670mm 770mm H 590mm Weight 30 kg 40 kg 55 kg 66 kg Optional Various work bases, various holders, Teaching Pendant, various work table, nozzle adjuster Conformity standard CE marking (few days release), EU RoHS (*1) depend on our prescribed method for measurement (method for measurement to follow JIS).

(*2) vary according to speed, movement pattern, embarkation center of gravity position. The Y-axis is price including work base (optional).New! Specifications for SX series

Series name SHOTmini

100SX

SHOTmini

200SX

SHOTMASTER

300SX

SHOTMASTER

400SX

SHOTMASTER

500SX

Model SM100SX-

3A-SS

SM200SX-3A-SS SM200SX

3A-Z-SS

SM200SX-4A-SS SM300SX-3A-SS SM300SX-4A-SS SM400SX-

3A-SS

SM400SX-

4A-SS

SM500SX-

3A-SS

SM500SX-4A-SS Control method (*1) PTP / CP control Control number of shaft center 3 axes 4 axis 3 axis 4 axis 3 axis 4axis 3 axis 4 axis Movement

RangeThe X,Y-axis 100mm 200mm 300mm 400mm 500mm The Z-axis 50mm 80mm The W-axis N.A N.A N.A ± 360° N.A ±360° N.A ±360° N.A ±360° Setting range

for PTP

operation

Speed

(*2)

The X,Y-axis 1~800mm/s The Z-axis 1~350mm/s 1~250mm/s 1~400mm/s The W-axis N.A 1~900°/s N.A 1~900°/s N.A 1~900°/s N.A 1~900°/s Setting range

for CP

Operation

Speed

(*2)

The X,Y-axis 0.1~800mm/s The Z-axis 0.1~350mm/s 0.1~250mm/s 0.1~400mm/s The W-Axis N.A 0.1~900°/s N.A 0.1~900°/s N.A 0.1~900°/s N.A 0.1~900°/s Repetitive

Positioning

Accuracy

(*3)

The X,Y-axis ±0.01mm The Z-axis ±0.01mm The W-axis N.A ± 0.01° N.A ± 0.01° N.A ±0.01° N.A ±0.01° Transportable

Weight

(*4)The Y-axis

(the work base side)

8 kg 15 kg Z,axis

(the head side)

2 kg 3.5 kg 2.5kg 7 kg 6kg 7kg 6kg 7kg 6kg Power supply, Power consumption AC100 - 240V 50/60Hz Power Consumption 100W 120W 200W 220W 200W 220W 200W 220W External form

Dimensions(*5)

W 202mm 300mm 510mm 610mm 710mm D 290mm 300mm 570mm 670mm 770mm H 440 mm 455 mm 555mm 590mm 690mm 590 mm 690mm 590mm 690mm Weight 11kg 13.3kg 14.5kg 15.5kg 37kg 40kg 55kg 58kg 66kg 69kg Interpolation 3D Line, 3D Circcular arc circle, 3D ellptic arc/ellpse, Spline Other function Synchroized Speed function * 1. PTP Control: This is for each specified axis to move to the end of coordinates at speed.

* 1. CP Control: This is for each specified axis to move to the end of coordinates at speed that

is synthesized by interpolation.

*2. These values very depending on the operations, such as the weight & gravity center of the located object,or other factors.

*3. This value is measured by the prescribed by Musashi.(method for measurement to follow JIS).

*4. When optinal are not mounted, the value varies with setting speed, setting of acceleration/deacceleration time and operation.

*5. W & D are the dimensions of the lower section of the case.

-

Following information is here ⇒ http://www.musashi-engineering.co.jp.e.cn.hp.transer.com/![]()